The Gresmalt Group is contributing to the United Nations’ Sustainable Development Goals by responsibly manufacturing building products and developing a long-term sustainable business that serves customers, employees and the communities in which it operates.

The Gresmalt Group, with over fifty years of manufacturing experience, is today one of the leading Italian producers of ceramic tiles. The company has experienced constant growth in turnover thanks to solid economic and financial management based on innovative capacity and attention to the environment and socio-economic context. The Gresmalt Group has placed environmental, social and economic sustainability at the centre of its business culture since 2005, when it was a pioneer in the ceramic sector and carried out its first environmental impact assessment with an LCA (Life Cycle Assessment) analysis. From that pilot experience began a process of continuous improvement of the production system to minimize the environmental impact by reducing the consumption of natural and energy resources.

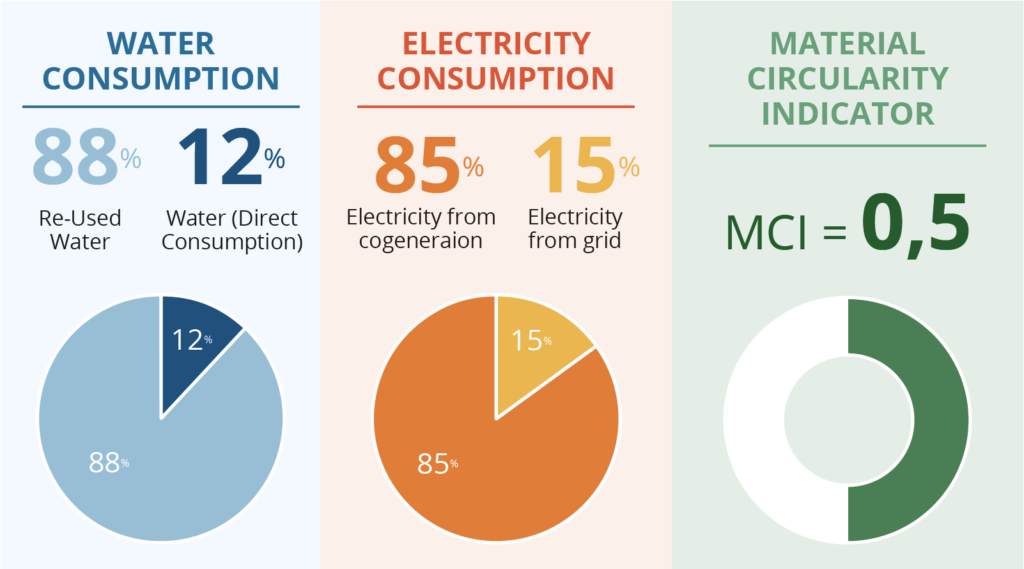

Since 2015, thanks to the support of the Italian Ministry of Economic Development and the European Commission, the Gresmalt Group has implemented an ambitious innovation project aimed at introducing the three pillars of sustainability (environment, economy and society) into its business model, transforming it from linear to circular. This model is based on a dynamic monitoring system able to measure the environmental and socio-economic impacts of the production process in real time thanks to the digital technologies of IoT and Industry 4.0, of which all plants have been progressively equipped.

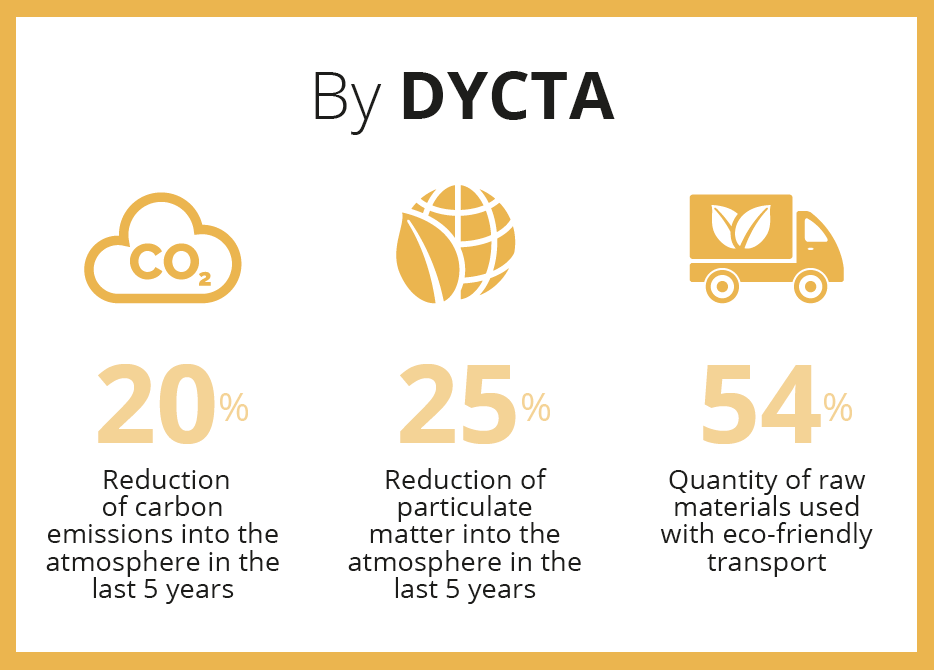

Compared to traditional impact assessment systems, which are based on historical, i.e. retrospective, inventory data, the new dynamic and digitized system called DYCTA (DYnamiC susTainability Assessment) is able to determine the impact that production activities have on the environment and society at the same time as they are produced, allowing for any immediate adjustment actions. In addition to monitoring the process, DYCTA is also able to support eco-design to predict how a new product, resource, or technology solution may impact the environment. It is thus possible to predict how changes to processes and materials can affect the ceramic product throughout its entire life cycle: from the raw materials to its use phase, up to the end of-life.

Finally, DYCTA can monitor deviations in real time from the company’s environmental goals and reference benchmarks.